Researchers at the Agile BioFoundry (ABF) and the Advanced Biofuels and Bioproducts Process Development Unit (ABPDU), have successfully scaled up a bio-based process that converts ethanol into a valuable precursor for consumer products, such as paints, coatings, and diapers. The researchers worked with industry partner, Industrial Microbes, to develop the technology.

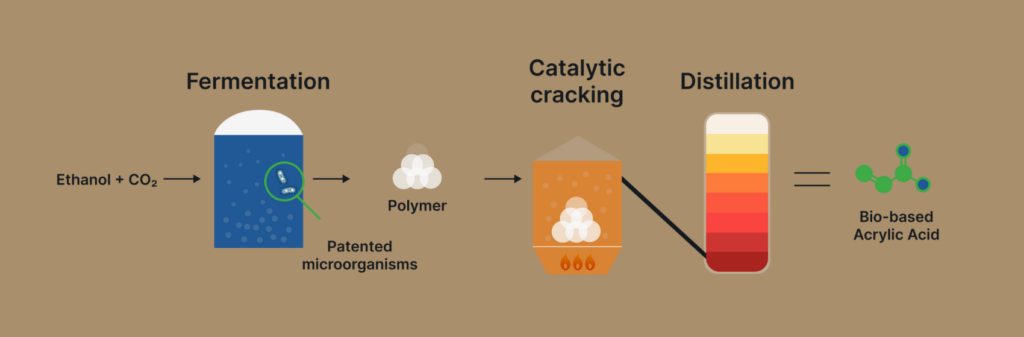

The process, successfully scaled up by ABF and ABPDU, produces poly(3-hydroxypropionate) or P3HP, a precursor to acrylic acid, widely used across the consumer product industry. Though it is typically sourced from petroleum, Industrial Microbes is developing a sustainable, bio-based process for producing acrylic acid. The company sought the expertise and equipment available at the ABF and ABPDU to help them scale up their process.

“In the early days of this type of work, maybe 20 years ago, a company might have spent several million dollars building their own pilot plant and training people,” said Noah Helman, CEO of Industrial Microbes. “But with the ABF and ABPDU, we can work directly with these world experts who’ve seen projects across the spectrum. The ability to access that expertise and drop into that infrastructure is unparalleled.”

Working with ABPDU’s Eric Sundstrom, the team performed several experiments to collect data and screen process conditions. They also screened the strain in the Sartorius Ambr® 250 system, which identified key process improvements.

The collaboration achieved a 300-liter scale production of P3HP. Now, Industrial Microbes has a product sample that they can use in application testing and for working with commercial producers. The low carbon footprint of this process has been attractive to these producers, Helman said.

“By continuously optimizing our process, we are confident that we can get to greater than a 75% reduction in carbon footprint, and possibly get to a net zero product,” Helman said. “Our partners are really excited about that.” The process successfully scaled up by ABF and ABPDU produces poly(3-hydroxypropionate) or P3HP, a precursor to acrylic acid, widely used across the consumer product industry.

“The strain scaled up beautifully and the key metrics at 300 L matched those from our lab. This is a testament to the robustness of the strain, the team that developed the process, and the expertise of researchers at the Agile BioFoundry,” said Elizabeth Clarke, CTO of Industrial Microbes.

The ABF team also led the application of high throughput proteomics — led by ABF scientist Chris Petzold — to inform strain engineering.

“The proteomics showed that we had too much expression of one of the pathway enzymes. Once we adjusted that, the performance improved,” Clarke said. “That was a very direct result of the fact that we had proteomics data available from ABF studies.”

Moving forward, the ABF team will be using the data collected in these experiments to train a predictive model that will suggest process improvements and strain engineering targets. This work, led by ABF scientist Philip Laible, aims to achieve predictive scale-up for Industrial Microbes’ P3HP production process. Clarke said she appreciated the flexibility of the ABF and ABPDU teams and the focus they had on making sure the project achieved their company’s goals.

“Early on in this project, we made changes to the process to lower the carbon footprint, which is very important to our customers,” she said. “Everyone at the ABF and ABPDU was immediately on board and focused on doing the work that was going to help us move as fast as possible.”

Following the 300-liter milestone, Industrial Microbes is working toward scaling up their process further and converting purified P3HP to acrylic acid. In discussions with commercial producers, Helman said the fact that they have already scaled up and generated prototype product that can be tested in real applications is a significant selling point.

“This partnership is accelerating the validation of both the scientific and the production conditions for our solutions, opening up the door to commercial partnerships for low-carbon footprint products,” Helman said. “At a time when bio-based products are seeing growing traction, the support from the ABF and ABPDU helped us get ahead of the curve.”

The ABF and ABPDU are supported by the U.S. Department of Energy’s Bioenergy Technologies Office.

This story was originally published on BETO’s Bioprose Blog.